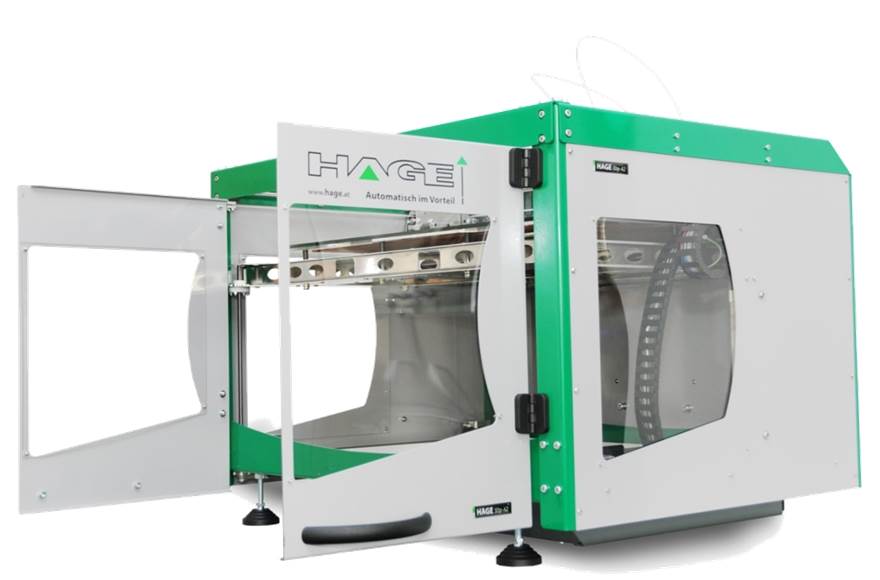

More space for accelerated processes

The really big printing chambers are available for all kinds of print-outs. Positioning accuracyup to 0.1 mm ensures a precise three-dimensional impression.

From special purpose machines to 3D-printers

Whether inputs and visions come from the market, from customers or from employees: at HAGE, we review ideas regarding their potential and invest in their realization. For example, one of HAGE’s development engineers had thevision of designing a 3D printing system for industrial use. Today: The solid HAGE3D printing systems are successfully in use and Europe-wide research projects are currently being conducted....

继续阅读完整内容

请查看下方广告以解锁文章剩余内容

More space for accelerated processes

The really big printing chambers are available for all kinds of print-outs. Positioning accuracy

up to 0.1 mm ensures a precise three-dimensional impression.

From special purpose machines to 3D-printers

Whether inputs and visions come from the market, from customers or from employees: at HAGE, we review ideas regarding their potential and invest in their realization. For example, one of HAGE’s development engineers had the

vision of designing a 3D printing system for industrial use. Today: The solid HAGE3D printing systems are successfully in use and Europe-wide research projects are currently being conducted.

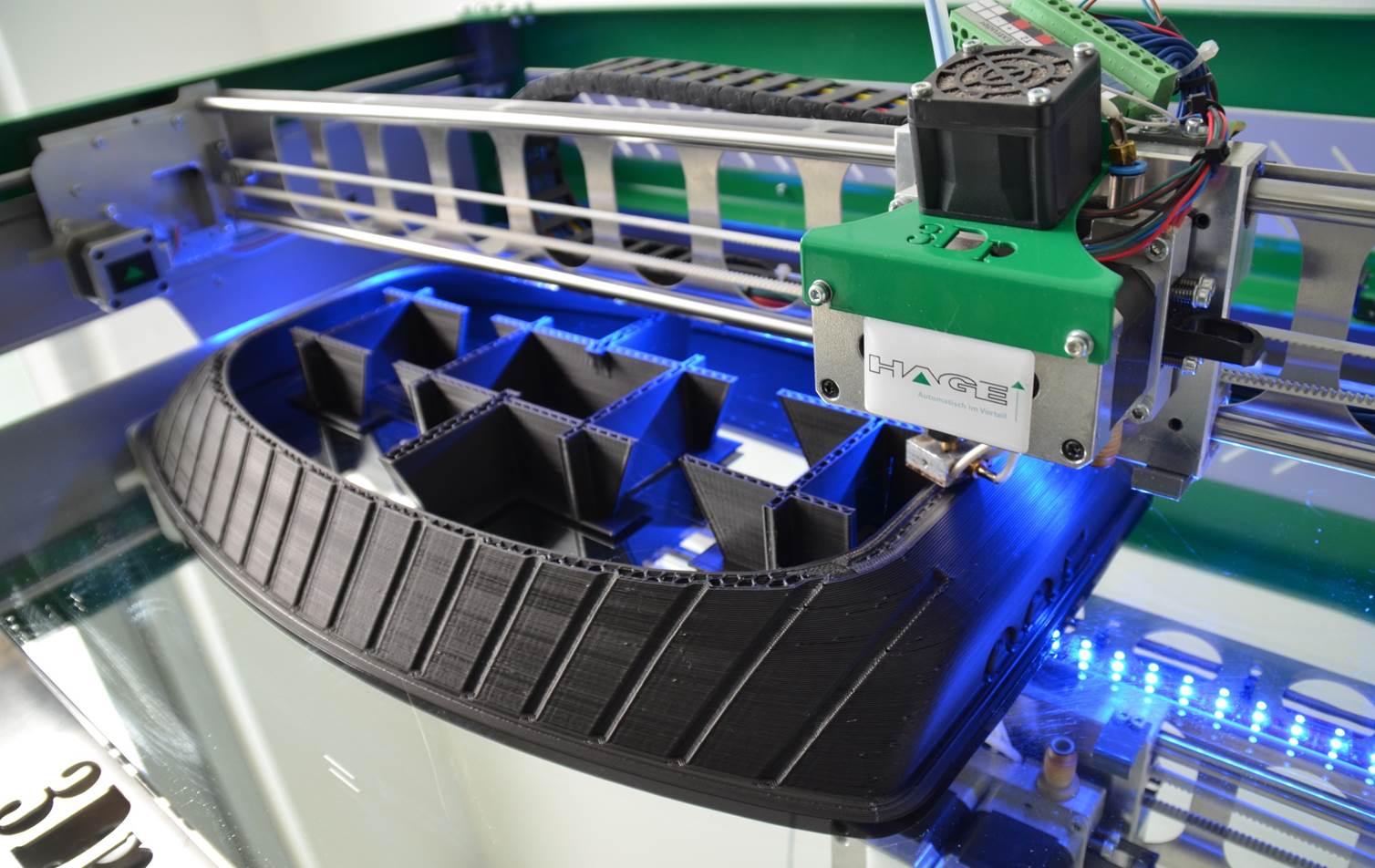

Versatile usage

- From design and prototype, to presentation objects and functional parts

- Allows for individual configurations, such as printing three materials

- Flexible part sizes

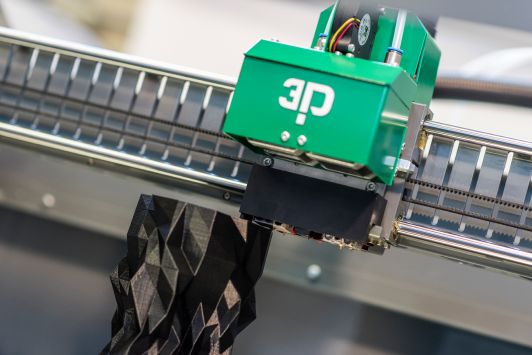

Precision makes an impression

- High quality of printing thanks to precision mechanical engineering – even at high speeds

- Evenness of the printing surface reduces waste and increases print quality

- The closed-loop stepping motor technology avoids step losses and provides exact positioning

Flexible printing

- Low filament costs thanks to flexible choice of materials (no vendor lock-in)

- Wide range of usable materials

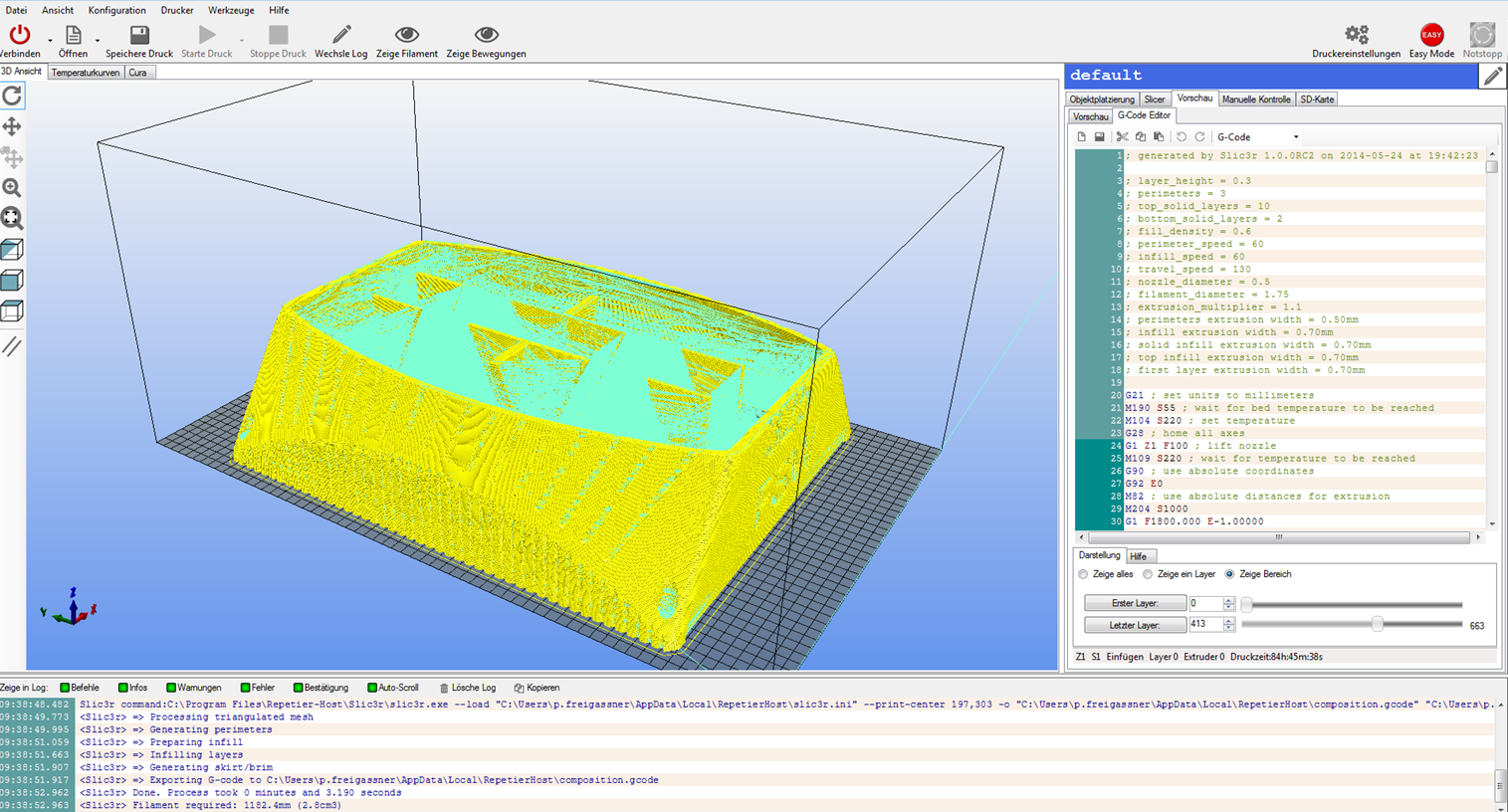

Professional slicing-software

Improve your print quality with Simplify3D®, the powerful 3D printing software that gives you total control for amazing 3D prints:

- Quick and Easy Startup

- High Performance Slicer

- Customizable Support Structures

- Animated Preview Mode

- Optimized Dual Extrusion

- Advanced Multi-Part Printing

Specifications:

Printing process: FFF (Rapid Prototyping)

Construction type: completely assembled

Power supply: 230V / 24V DC

Compressed air supply required

External dimensions :1450 x 1250 x 1060 mm

weight: ca. 400 kg

LED Innenraumbeleuchtung

manufacturer: HAGE Sondermaschinenbau GmbH & Co KG

manufacturer's warranty: 12 months

XXL printer volume size: 700 x 500 x 400 mm

Print bed: heated up to 110°C, heating power 1000 W

Print head: dual extruder with hot-end temperature up to 300°C (standard) optional: up to 450°C*

Hage Filament Feeding System HFFS™

Active component cooling

Nozzle diameter: 0,3mm to 0,5mm (0,4 mm standard)

Positioning accuracy: in xy 0,05mm

Layer thickness: from 50 μm

Movement speed: XY ~ 400 mm/s, Z ~ 300mm/min

Printing speed: up to 150 mm/s( depends on material)

Touch-Screen 7“

Industry control Sigmatek, HAGE software

2 workstation (up to 4 devices) Slicing software inclusive (Simplify3D)

Stand Alone printing with USB

Ethernet interface

Remote access

Event-Mailing Funktion

Allows USB „Stand alone“ print 84

Flexible choice of materials (no vendor lock-in)

Filament diameter: 1,75mm

Printable materials: ASA, M-ABS, PET-G, PC-ABS sowie Nylon*, PSU*, PEI*, PC-PEI* Peek*

Support & Service

- Completely assembled, adjusted and put into operation on site

- On-site service, intensive user training, user support and 3D engineering